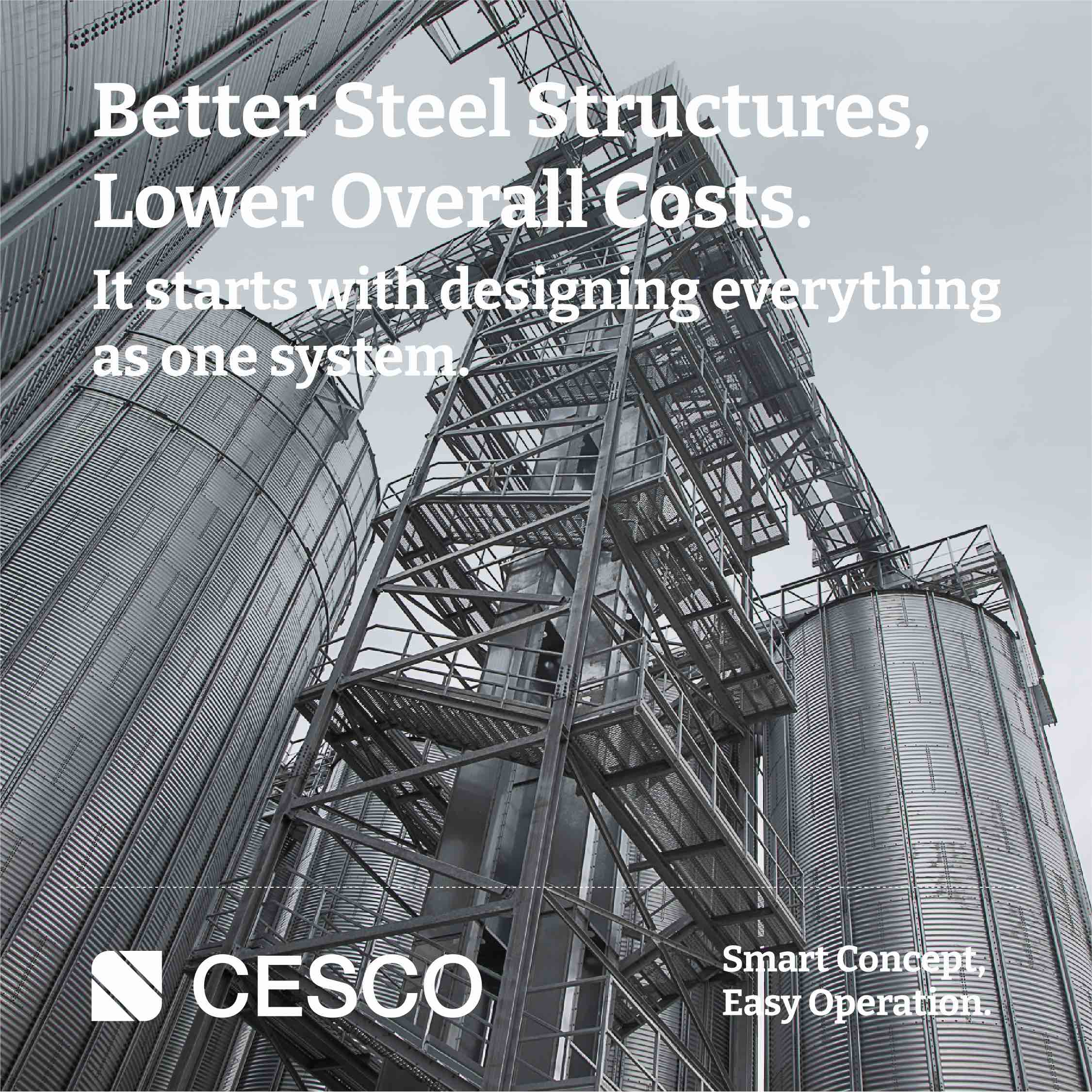

Better Steel Structures, Lower Overall Costs. It starts with designing everything as one system.

When building a new processing plant, the steel structure and the process bins are typically designed by different teams. This separation can lead to design issues, more complicated foundations, and a tougher assembly process on site.

CESCO EPC handles this differently. We use an integrated approach, designing the steel structures and the process bins together from the very beginning.

What does this mean for the project?

First, the foundations can be simpler and faster to build because the entire structure is designed to work together, improving how loads are managed.

We also use high-yield S350 steel for main beams and a heavy zinc coating for corrosion resistance, which helps the structure last longer. And because most components are bolted together in the field instead of welded, assembly is faster and the protective coating isn’t damaged.

This process also helps with sanitation. The design of the steelwork avoids horizontal surfaces where dust and pests can accumulate. Inside the bins, surfaces are kept smooth with countersunk screws and rounded corners to make cleaning easier and prevent material buildup.

By looking at the total project, this approach helps lower the overall investment. It reduces the chance of hidden expenses related to complex construction, on-site modifications, and long-term maintenance.

See how integrated design can work for your next project.

Contact us here CESCO EPC