CESCO Successfully Completes Factory Acceptance Test for Bagging Line System in Saudi Arabia

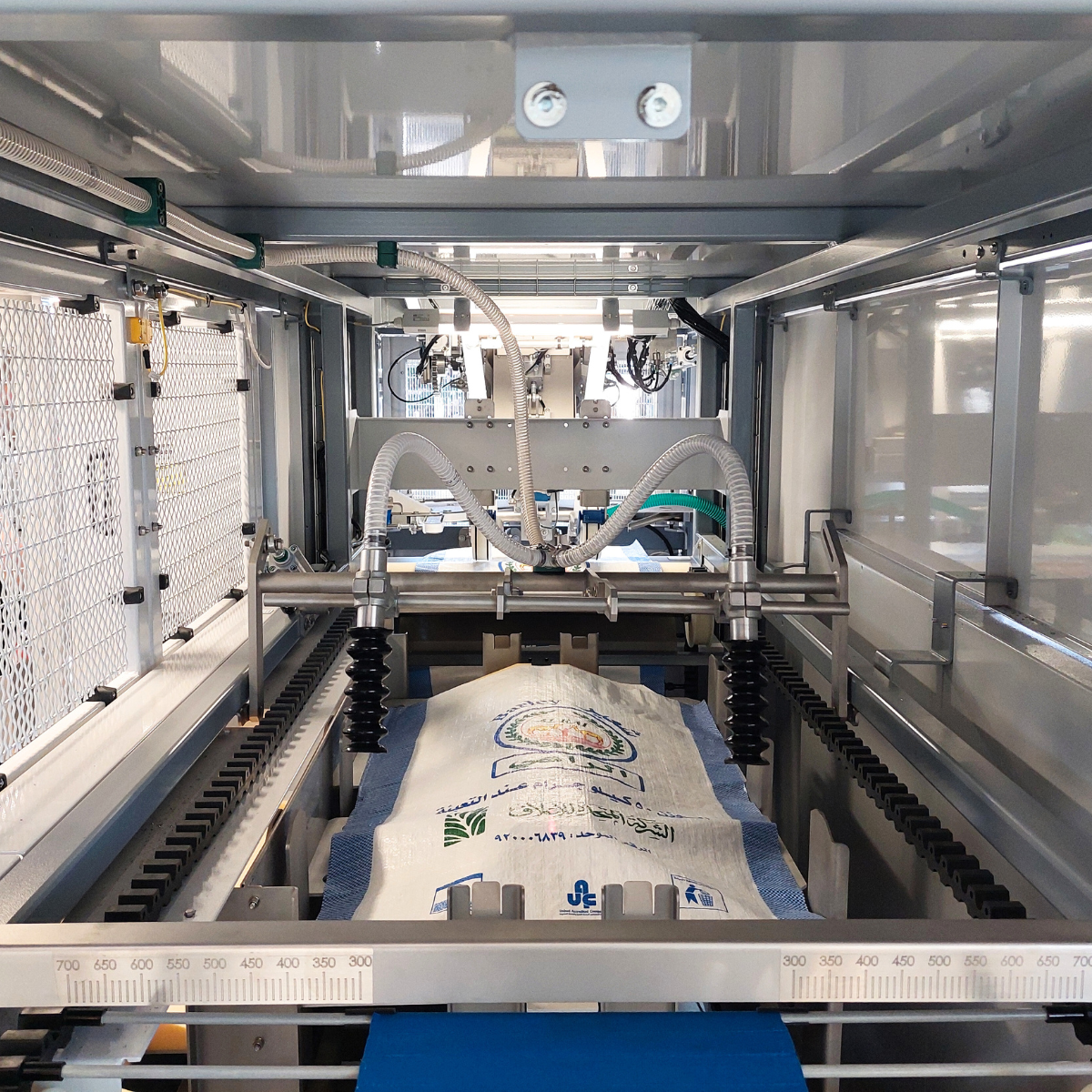

We are proud to announce the successful completion of the Factory Acceptance Test (FAT) for our high-capacity bagging line system, developed as part of our project with United Feed Company (UFC) in Saudi Arabia. This milestone, achieved on October 31st at our supplier’s facility, highlights our commitment to on-time delivery and top-quality standards.

The FAT validated our system’s ability to operate across four parallel lines, each capable of processing up to 1,000 bags of 50 kg per hour with UFC’s specified bags. During testing, we conducted safety checks, speed and cutting tests, as well as verifications of the ink printer and belt conveyors. These tests ensured that all equipment components meet rigorous operational and safety standards. A second round of testing will take place at the project site once installation is complete and products are in place.

With shipment scheduled for mid-November, we remain on track to deliver this advanced equipment as planned.

“Achieving this milestone demonstrates our commitment to timely execution and high quality for our partners,” stated Martino Celeghini, CEO of CESCO. “Our collaboration with UFC supports Saudi Arabia’s agricultural and food security goals, and we look forward to completing the project as planned.”

The bagging line is a key component of a modern grain storage and handling facility we are building in partnership with UFC, a leader in Saudi Arabia’s food industry since 1985. This facility will provide high-quality animal feed for the poultry and livestock sectors, including essential grains such as barley.

Project Highlights:

- Large-Scale Storage Capacity: The facility includes 15 corrugated steel silos with a combined capacity of 205,000 tons, along with a 3,800 m² flat storage warehouse for soy meal.

- High-Capacity Handling Systems: Grain (2×400 t/h) and soy meal (2×125 t/h) receiving lines ensure efficient intake of materials.

- Advanced Pre-Cleaning and Weighing: Integrated systems remove impurities and provide accurate weighing of materials.

- Flexible Reclaiming and Distribution: Materials can be directed as needed to bulk truck loading, bagging lines, or storage.

- Future-Ready Design: The facility allows for an additional 120,000 tons of storage capacity, offering scalability to meet UFC’s future needs.

With this achievement, we continue advancing our mission to provide high-quality grain storage and processing solutions that support efficiency and growth for our clients in strategic markets.