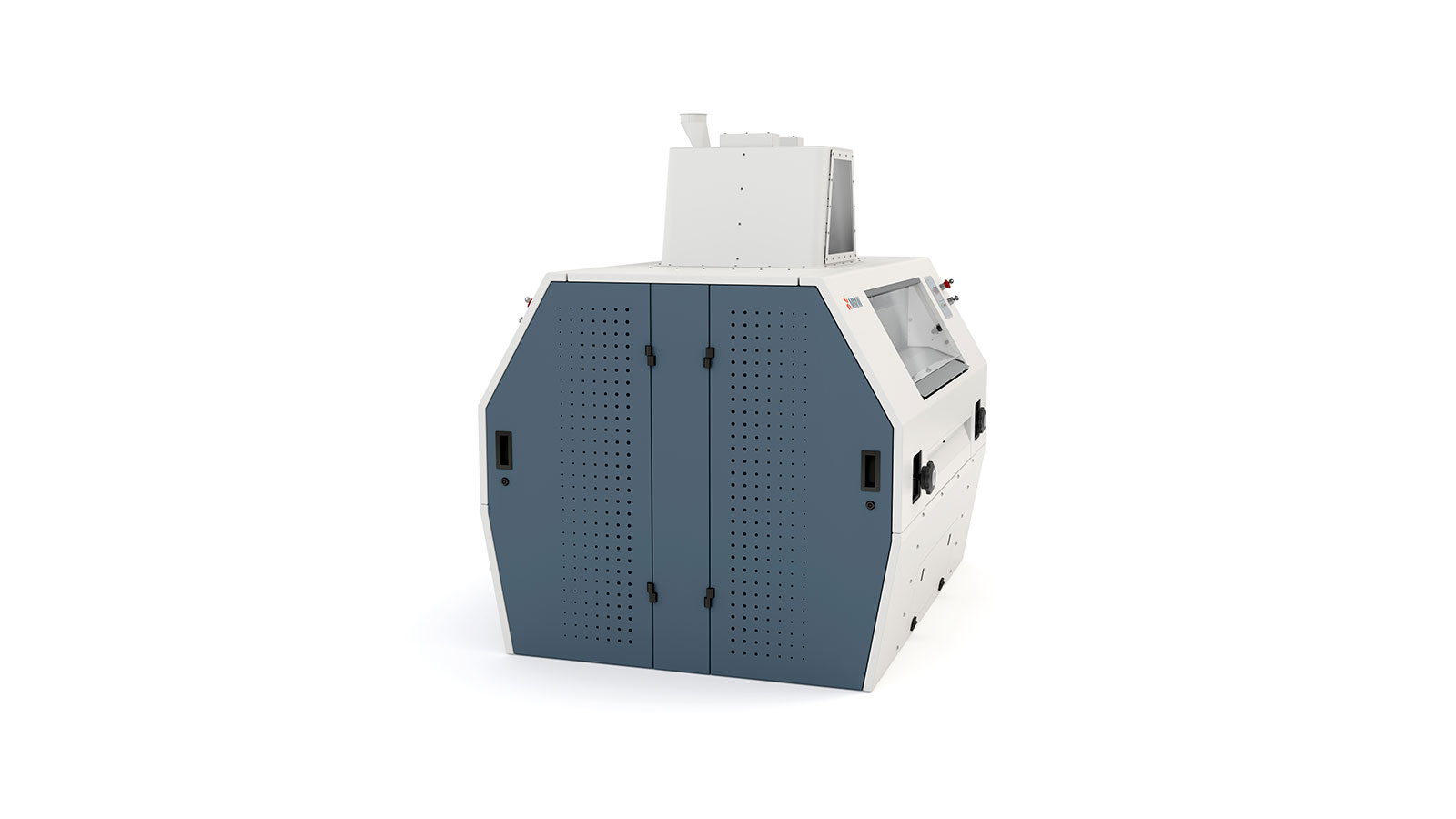

Double roller mill RM 0600250 0600300 0800250 0800300 1000250 1000300

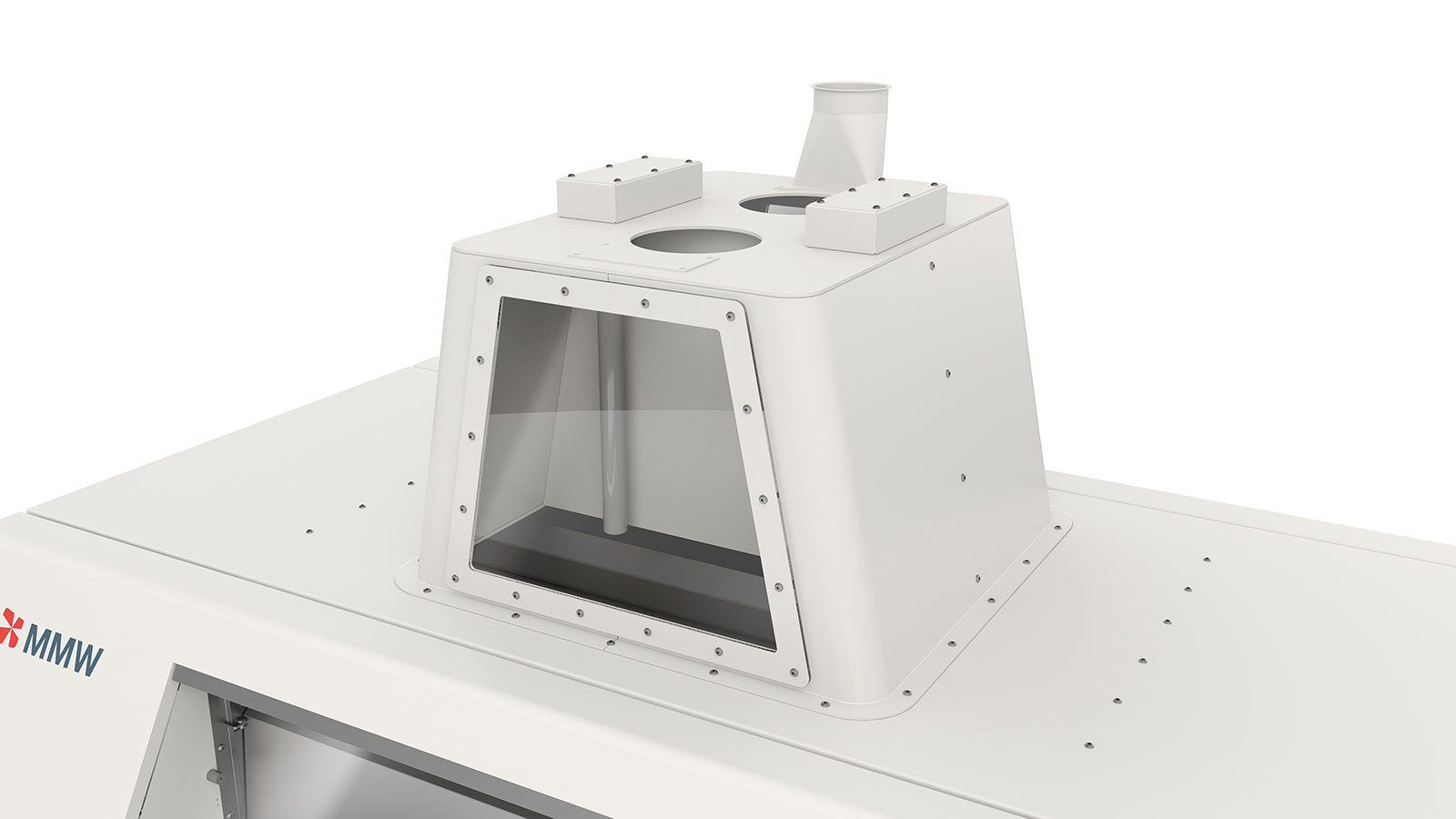

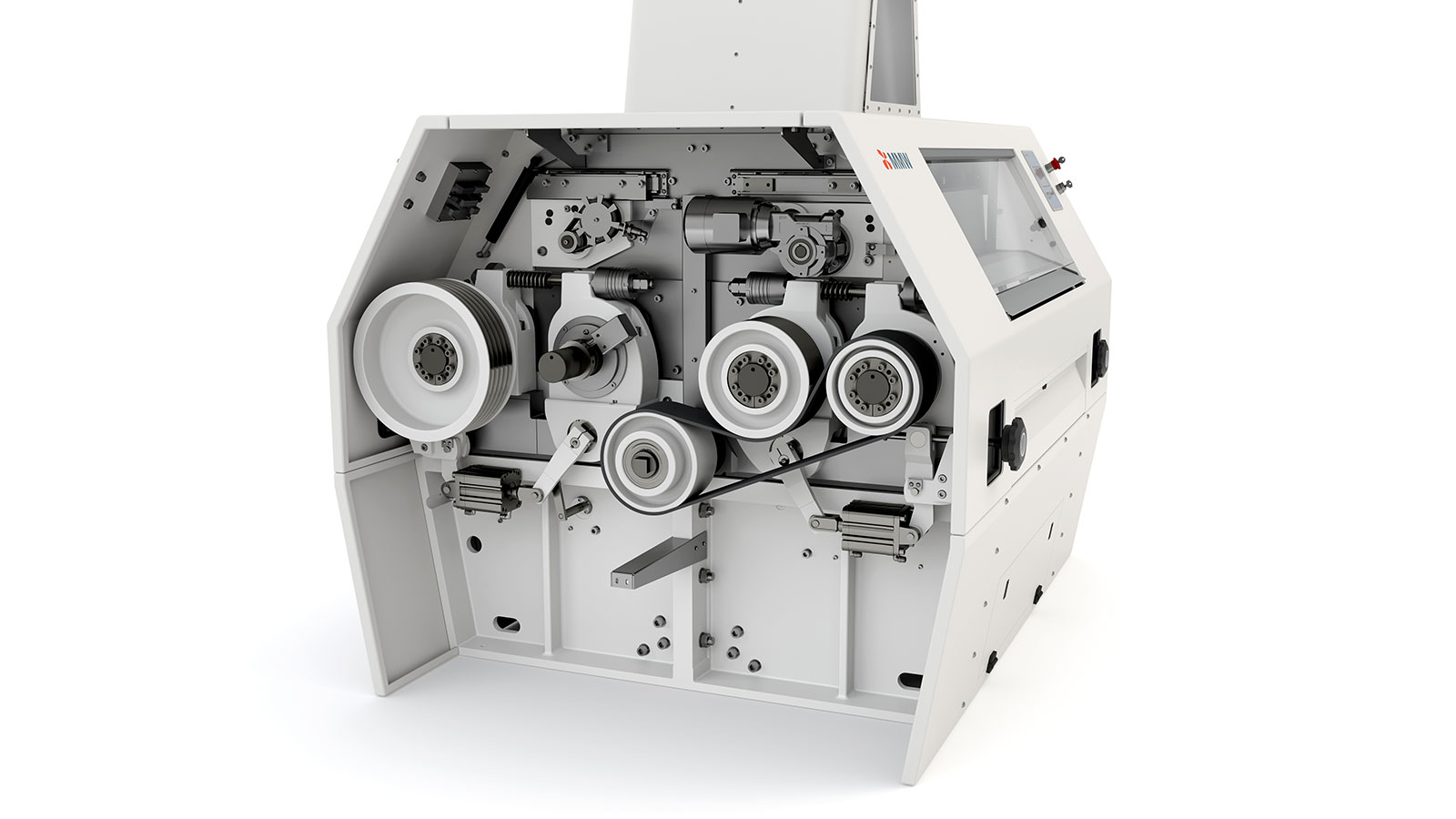

The roller mill is a crucial machine in any milling plant, primarily used for grinding various grains, including wheat, into flour and bran. It consists of horizontal rollers, which are available in two different diameters, 250 mm or 300 mm, and two different finishing options: smooth or striped. Each side of the roller mill can be adjusted independently to allow separate grinding of different fractions. The mill has a cast iron frame and can be finished in food-grade paint coating or stainless steel.