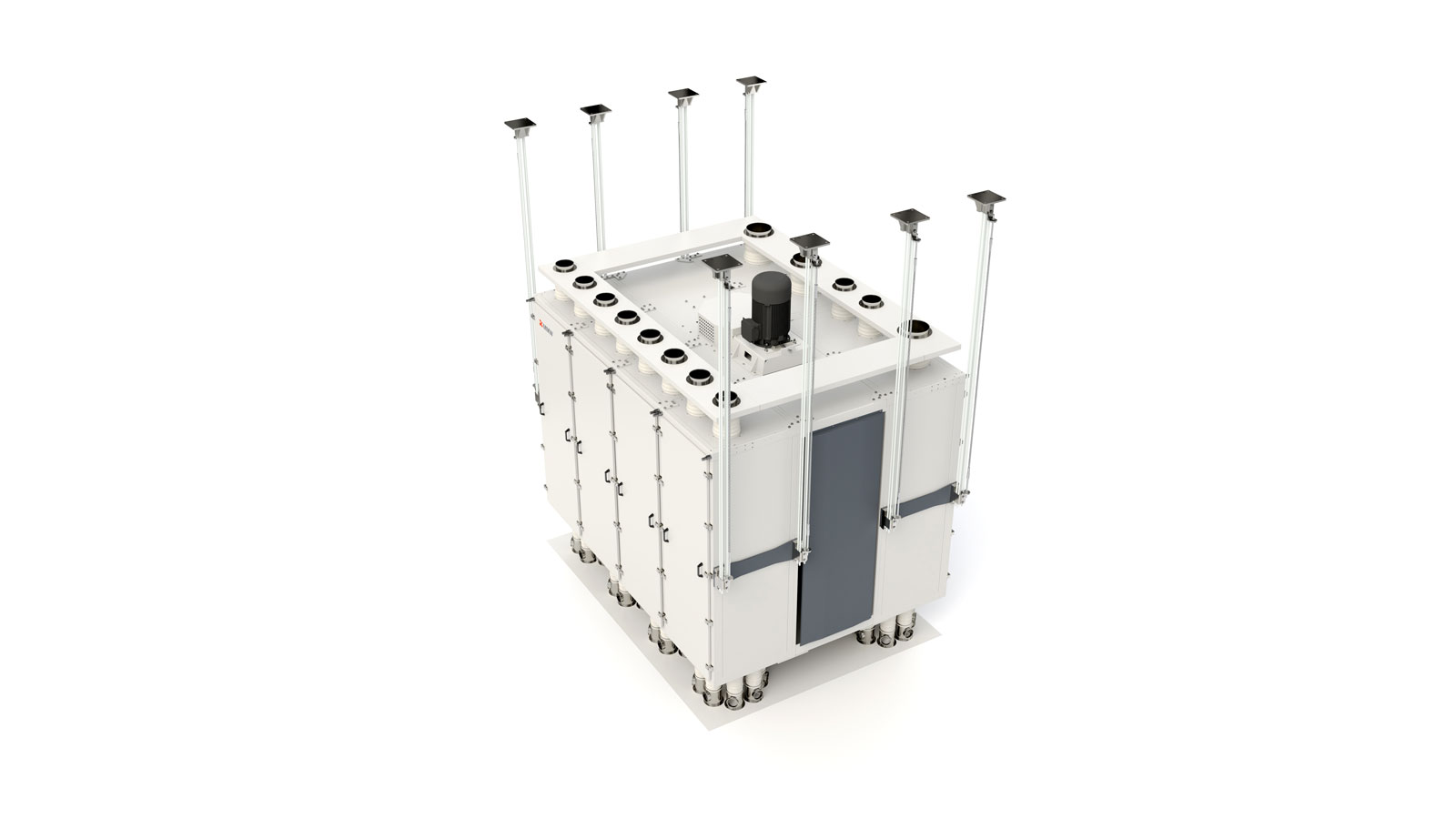

Plansifter PLS 04 06 08 10

The plansifter is a highly efficient sorting machine that is commonly used to separate products from various roller mills or grinders. It operates in a circular motion in a horizontal plane, with the product flowing from top to bottom through a path known as the sieve channel. As the product drizzles down, only a portion of it passes through the sieves while the rest remains on the screen cloth.